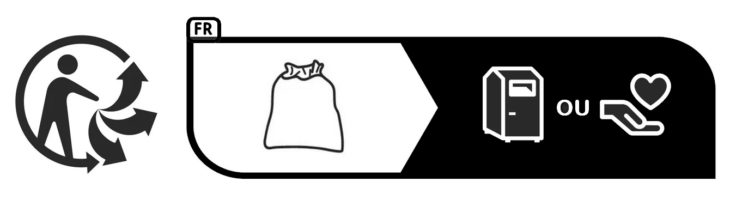

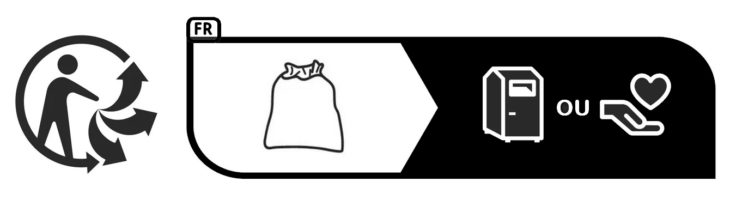

For the French market, the “triman” pictogram is mandatory on all products covered by a sorting notice.

The French AGEC law (anti-waste circular economy law), in its application decree no. 2021-385 of 29 June 2021, defines the use of the “triman” sign and “sorting instructions”.

The symbolism of the “triman” is as follows: the human silhouette represents the citizen gesture, the three arrows the sorting and the circular arrow the recycling. Here, the paving stone of the sorting instructions indicates that a pouch is recycled either in a textile container or given to a charity.

A light, thin fabric made of cotton, viscose or silk.

Synthetic fiber made from cellulose, woven alone or with other synthetic fibers. This fiber is used to produce highly comfortable fabrics. Cellophane, rayon and fibranne are made from viscose.

Threads which, with the warp threads, are used to weave fabric. These are the threads parallel to the width of a piece of fabric. See warp and weft.

Number of dots per cm². Gray value expressed by relative surface area printed. Screen angles: angles at which the halftones of a separated color are made to output to a lithographic film. An incorrect angle screen may lead to moiré patterns.

Document having a single pure color tone and a pure white excluding all color gradients.

– see Waste – Manufacturing tolerance is an important concept to be aware of. To make custom and/or personalized packaging, a greater product quantity than the one ordered is always planned to account for the waste. If there is a lot of waste, less packaging will be produced and if the waste is low, there will be more product. This amount of produced packaging is thus the exact quantity that will be shipped and billed to the customer. The manufacturing tolerance in our industry is 10% more or less.

One of the three fundamental types of textile weaves alongside satin and twill weave, plain weave is the oldest and the simplest. Plain weave fabrics have no right or wrong side and all fibers may be woven in a plain weave.

A soft and strong surface made of a regular assembly of warp and weft threads. This assembly is done on a machine called a loom.